Plate Heat Exchanger

Plate Heat Exchanger Specification

- Product Type

- Plate Heat Exchanger

- Material

- Stainless Steel

- Capacity

- 1000-10000 LPH Ltr/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Power

- 2-5 kW Watt (w)

- Voltage

- 220/380 V Volt (v)

- Weight

- 250-650 kg Kilograms (kg)

- Color

- Blue

- Warranty

- 1 Year

- Gasket Material

- NBR / EPDM / Viton

- Cleaning

- CIP (Clean In Place)

- Maximum Operating Pressure

- 10 Bar

- Application

- Milk, Juice, Beverage, Chemical, Dairy

- Maximum Temperature

- 180C

- Number of Plates

- 10-200 plates

- Connection Type

- SMS / DIN / Threaded / Flanged

- Frame Material

- Powder Coated Carbon Steel / Stainless Steel

- Design

- Compact Modular Design

- Heat Transfer Area

- 5-200 m

- Plate Material

- SS304 / SS316L

Plate Heat Exchanger Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

About Plate Heat Exchanger

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. The major advantage over convetional heat exchanger is that the fluids are exposed to a much larger surface area because the fluids spread out over the plates and facilitates the transfer of heat.

A plate heat exchanger consists of a series of thin, corrugated plates and these plates are gasketed, welded or brazed together depending on the application. The plates are compressed together in rigid frame to form an arrangement of parallel flow channel with alternating hot and cold fluids.

The advantage of plate heat exchanger compared to shell and tube heat exchanger is it requires less floor area, large heating area, the temperature approach in plate heat exchangers may be as low as 1 Degree C, increase and reduction of heating area is simple.

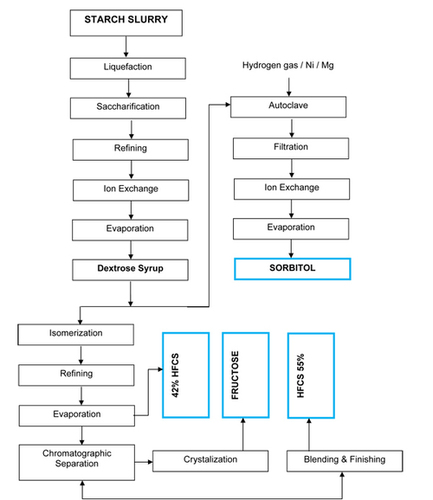

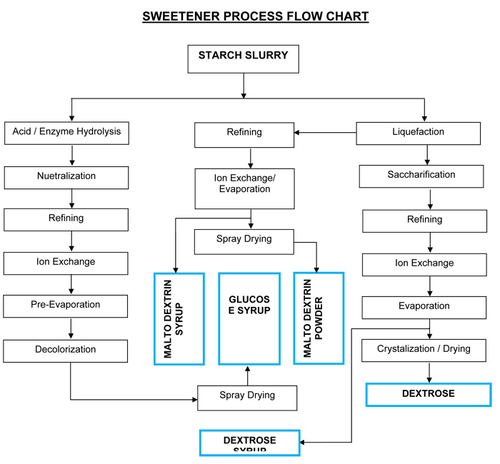

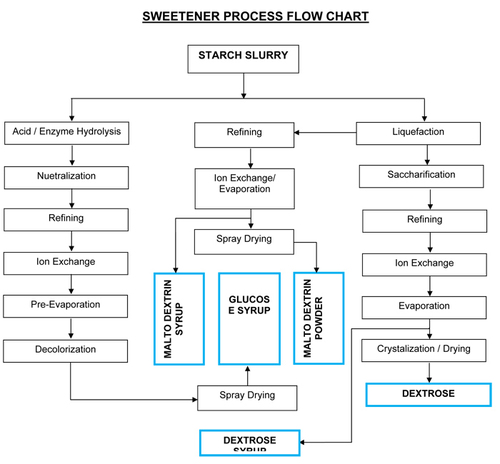

Plate heat exchangers are used in sweetener process to heat or cool the glucose syrup at different location.

Versatile and Efficient Plate Heat Exchange

This plate heat exchanger handles a wide variety of liquids, making it suitable for dairy, beverage, juice, and chemical industries. Its modular, compact design allows for easy integration into new and existing processing systems, optimizing energy utilization and reducing operational footprints.

Advanced Construction for Demanding Environments

Built with premium stainless steel plates and robust powder-coated carbon steel or stainless steel frames, this unit resists corrosion and maintains performance under harsh conditions. The use of high-quality gaskets and multiple connection types further enhances chemical and thermal resistance.

Automated Operation and Easy Maintenance

Fully automatic and PLC-controlled, this heat exchanger streamlines processing while enabling straightforward maintenance through CIP (Clean In Place) design. Operators benefit from reduced downtime and consistent output, supporting demanding production schedules.

FAQs of Plate Heat Exchanger:

Q: How does the plate heat exchanger process milk, juice, and beverage applications?

A: Milk, juice, and beverages pass through alternating channels in the compact plates, allowing efficient thermal exchange without direct contact. This ensures rapid and gentle heating or cooling, maintaining product integrity and quality during processing.Q: What types of materials are used in the plate and frame construction for chemical compatibility?

A: Plates are manufactured from SS304 or SS316L stainless steel, offering excellent corrosion resistance. Frames utilize powder-coated carbon steel or stainless steel for durability, while gaskets (NBR, EPDM, Viton) are selected to suit chemical and thermal requirements.Q: When is CIP (Clean In Place) cleaning recommended for this heat exchanger?

A: CIP cleaning should be performed routinely in dairy, beverage, and chemical operations to maintain hygiene and prevent contamination. The systems design supports frequent automated cleaning without disassembly, promoting continuous, safe production.Q: Where can the plate heat exchanger be installed in a processing plant?

A: Its modular, compact design allows installation in a variety of locations, including milk, juice, beverage, and chemical processing lines. It adapts to both new and retrofit projects due to its flexible connection typesSMS, DIN, threaded, or flanged.Q: What is the main benefit of using a compact modular plate heat exchanger in industrial processes?

A: The primary benefit is highly efficient energy transfer with minimal space requirement. This results in lower operational costs, faster heating or cooling cycles, and adaptability to different production capacities and applications.Q: How many plates does the system accommodate, and what is its processing capacity?

A: This model accommodates from 10 to 200 plates, providing a heat transfer area of 5 to 200 m. It processes flow rates from 1000 to 10000 liters per hour, supporting a wide range of industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sweeteners Processing Category

Sorbitol Syrup Machine

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : Stainless Steel

Color : Silver

Product Type : Sorbitol Syrup Machine

Ion Exchange Column

Minimum Order Quantity : 1 Piece

Computerized : No

Material : FRP (Fiber Reinforced Plastic)

Color : Grey

Product Type : Ion Exchange Column

Warranty : 1 Year

Maltose Malto dextrin

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : Stainless Steel

Color : White

Product Type : Maltose Malto Dextrin

Warranty : 1 Year

Glucose Acid Enzyme

Minimum Order Quantity : 1 Unit

Computerized : No

Material : Enzyme Preparation

Color : White/OffWhite Powder

Product Type : Glucose Acid Enzyme

Warranty : 1 Year

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese