Glucose Acid Enzyme

Glucose Acid Enzyme Specification

- Product Type

- Glucose Acid Enzyme

- Material

- Enzyme Preparation

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Power

- 5-10 kW Watt (w)

- Voltage

- 220-440 V Volt (v)

- Color

- White/Off-White Powder

- Warranty

- 1 Year

- Form

- Powder

- Enzyme Activity

- High Activity Glucoamylase

- Shelf Life

- 12-24 Months

- Application Area

- Starch to Glucose Conversion

- Purity

- >90%

- Storage Condition

- Cool, Dry Place

- Usage

- Industrial, Food & Beverage, Pharmaceuticals

- Solubility

- Water Soluble

- CAS Number

- 9032-08-0

- Packaging Type

- HDPE Drums or Bags

Glucose Acid Enzyme Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 7 Days

About Glucose Acid Enzyme

Glucose Acid / Enzyme :

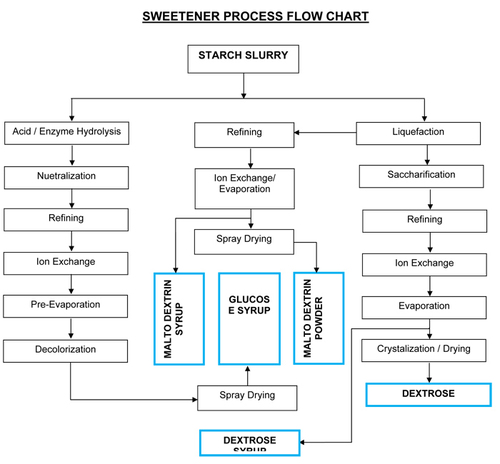

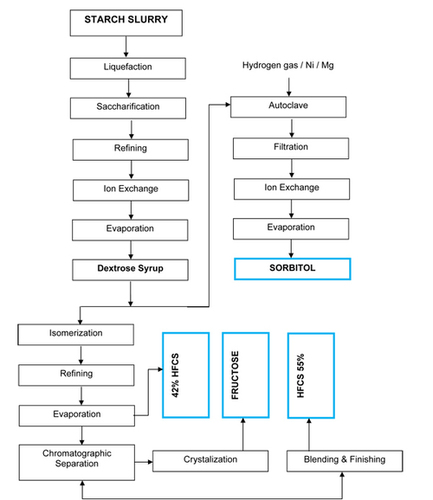

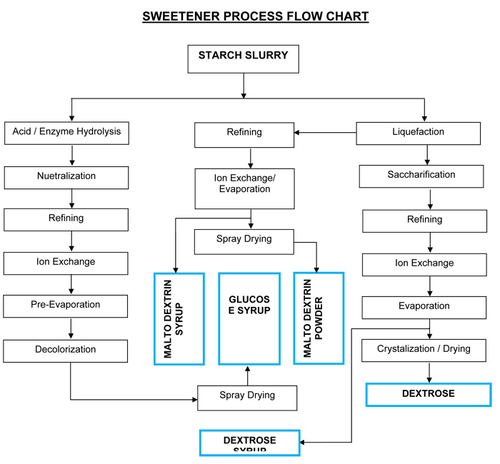

Glucose syrup is prepared by both acid and enzyme process. In acid process the starch slurry is prepared for conversion by adjusting the pH and concentration and fed to the continuous indirect acid convertor and the temperature, DE value is auto controlled to get continuous output of desired DE value. The obtained syrup is neutralized, filtered to remove mud and protein impurities and then passed through ion exchange column to remove the ionic impurities and reduce the ash content and finally concentrated to 8286% DS in triple effect evaporator.

Whereas in enzyme hydrolysis the slurry is prepares by adding enzyme and pH adjustment and passed through jet cooker system wherein direct steam and slurry get in contact and heat and convert starch into glucose, the syrup is hold in holding columns for 2 hours and neutralized and taken into saccharifcation tanks for second enzyme dosing and further DE value is increased to desire level, filtered to remove protein and passed thorugh ion exchange columns to remove ionic impurities and reduce the ash content and concentrated to 8286% DS in triple effect evaporator.

Efficient Starch to Glucose Conversion

Specially engineered for industries requiring rapid and effective starch hydrolysis, this Glucose Acid Enzyme exhibits high glucoamylase activity. Its excellent solubility in water and consistent performance guarantee an efficient conversion process, optimizing output in food, beverage, and pharmaceutical manufacturing.

Superior Purity and Shelf Stability

With a purity exceeding 90%, this enzyme preparation ensures minimal impurities and superior performance. Packaged securely in HDPE drums or bags, and with a shelf life ranging from 12 to 24 months, it remains stable and effective when stored under recommended cool, dry conditions.

Designed for Industrial Automation

This enzyme powder integrates seamlessly with modern industrial systems, supporting automatic operation through PLC controls. It operates safely within a voltage range of 220-440 V and adapts to a variety of processing environments, making it suitable for exporters, manufacturers, and suppliers.

FAQs of Glucose Acid Enzyme:

Q: How is Glucose Acid Enzyme powder used in industrial starch processing?

A: Glucose Acid Enzyme powder is added to starch solutions, where its high glucoamylase activity breaks down starch molecules into glucose. This process can be controlled and automated via PLC systems, ensuring efficiency and consistency in food, beverage, and pharmaceutical production settings.Q: What are the advantages of using this enzyme for starch to glucose conversion?

A: Its high enzyme activity, superior purity, and excellent water solubility result in fast, thorough starch hydrolysis and high glucose yield. This translates to improved product quality, reduced processing times, and suitability for varied industrial applications.Q: When should the Glucose Acid Enzyme powder be applied during processing?

A: This enzyme is usually introduced during the liquefaction or saccharification stages of starch processing. Adding it at these points ensures optimal breakdown of starch into glucose, maximizing the efficiency of the conversion process.Q: Where should Glucose Acid Enzyme be stored to maintain its activity?

A: Store the enzyme powder in a cool, dry place and ensure it remains sealed in its HDPE drum or bag. This storage method protects the enzyme from moisture and temperature fluctuations, preserving its potency throughout the 1224 month shelf life.Q: What is the recommended packaging for this enzyme and why?

A: Glucose Acid Enzyme is offered in durable HDPE drums or bags, which safeguard the powder against contamination, moisture, and physical damage during handling and transportation, making them ideal for domestic and export markets.Q: How does the PLC control system benefit enzyme application?

A: The PLC control system enables automated and precise dosing of the enzyme during processing, improving operational safety, enhancing batch consistency, and reducing manual intervention. This ensures optimal enzyme performance in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sweeteners Processing Category

Plate Heat Exchanger

Minimum Order Quantity : 1 Piece

Computerized : No

Product Type : Plate Heat Exchanger

Color : Blue

Material : Stainless Steel

Automatic Grade : Automatic

Sorbitol Syrup Machine

Minimum Order Quantity : 1 Unit

Computerized : Yes

Product Type : Sorbitol Syrup Machine

Color : Silver

Material : Stainless Steel

Automatic Grade : Automatic

Ion Exchange Column

Minimum Order Quantity : 1 Piece

Computerized : No

Product Type : Ion Exchange Column

Color : Grey

Material : FRP (Fiber Reinforced Plastic)

Automatic Grade : SemiAutomatic

Maltose Malto dextrin

Minimum Order Quantity : 1 Unit

Computerized : Yes

Product Type : Maltose Malto Dextrin

Color : White

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese