Single Effect Evaporator

Single Effect Evaporator Specification

- Product Type

- Single Effect Evaporator

- Material

- Stainless Steel (SS304/SS316)

- Capacity

- 500 Liters/hr to 10,000 Liters/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic, Automatic

- Control System

- PLC Based, Manual

- Power

- 15 kW to 100 kW

- Voltage

- 380V / 415V / 440V

- Current

- Variable Depending on Model

- Weight

- Depends on Capacity (Approx. 1.2 to 5 Tons)

- Color

- Silver

About Single Effect Evaporator

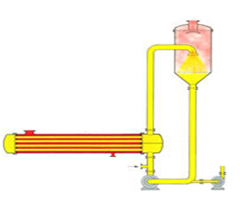

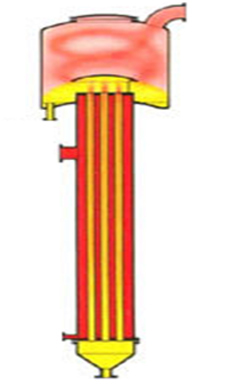

Batch / Single Effect Evaporator

Single effect evaporator contained a single vertical cylinder. In the centre of the cylinder there is a steam heating section, with pipes passing through it in which the evaporating rise. At the top of the cylinder, there are baffles, which allow the vapours to escape but check liquid droplets that may accompany the vapours from the liquid surface.

Short tube (batch) evaporator used for final concentration of syrup. In glucose making companies carbon treated & pre-concentrated glucose syrup is passed through single effect evaporator to obtain 85~86% solids glucose syrup. This happens under vacuum and vapor is extracted and condensed in a barometric condenser. This range of evaporator is tailor-made to fit the plant capacity.

Applications:

Malt mix slurry

Malt mix slurry  Starch

Starch Mango pulp paste

Mango pulp paste  Sugar Syrup

Sugar Syrup Tomato paste

Tomato paste Herbal extract

Herbal extract

Versatile Applications in Key Industries

Designed to meet the demanding needs of pharmaceutical, food processing, and chemical manufacturing, our Single Effect Evaporator offers versatile solutions for diverse production environments. Its customizable features and high-grade stainless steel construction ensure compliance with industry standards, making it ideal for applications where hygiene and process integrity are critical.

Advanced Automation and Safety Integration

Equipped with modern PLC-based controls, level and temperature sensors, and flow meters, the evaporator delivers reliable automated performance. Safety is prioritized with overpressure protection, emergency shutdowns, and optional mixing arrangements, providing a robust operational environment with minimal manual intervention required.

Flexible Design and Long Service Life

Engineered for both horizontal and vertical installations, our evaporator adapts to space constraints while offering low-maintenance operation. With a durable, polished finish and high-grade materials (SS304/SS316), it delivers more than ten years of service and evaporation rates up to 95%, ensuring sustained productivity and minimal downtime.

FAQs of Single Effect Evaporator:

Q: How does the Single Effect Evaporator benefit pharmaceutical and food industry operations?

A: The evaporator efficiently concentrates liquid products and solutions, ensuring consistent quality and purity. Its polished stainless steel construction meets strict regulatory standards, while advanced automation guarantees reproducibility and safety during processing.Q: What heating sources can be used with this evaporator?

A: Both steam and electricity are compatible heating sources, allowing facilities to choose based on available infrastructure, energy efficiency goals, and product requirements.Q: When should a user consider requesting a mixing arrangement?

A: A mixing arrangement is recommended when processing solutions that require uniform consistency, handling viscous materials, or when components tend to settle. This ensures homogeneous evaporation and improved final product quality.Q: Where is installation possible, and can the orientation be customized?

A: The unit can be installed in a variety of industrial settings, with both horizontal and vertical mounting options available. Our team assists with site assessment to recommend the optimal configuration for space and process flow.Q: What process control features enhance operation and safety?

A: The system employs PLC-based controls, along with level and temperature sensors, flow meters, and automatic overpressure protection. Emergency shutdown systems further enhance safety and operational reliability.Q: How is maintenance addressed, and what is the expected service life?

A: Maintenance is minimal due to the use of high-quality materials and a streamlined design. With proper use, the evaporator offers a service life exceeding ten years, reducing operational interruptions and repair costs.Q: What after-sales support is available to exporters, manufacturers, and suppliers in India?

A: Comprehensive after-sales service is provided, including installation assistance, technical support, and maintenance guidance, ensuring long-term satisfaction for clients across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Evaporators Category

Force Circulation Evaporator

Voltage : 240V/380V

Capacity : Customizable

Color : Yellow

Product Type : Evaporator

Computerized : Yes

Automatic Grade : Automatic

Rising Film Evaporator

Voltage : 220 V / 380 V / 415 V

Capacity : 500 LPH to 20000 LPH (customizable)

Color : Silver/Grey

Product Type : Rising Film Evaporator

Computerized : No

Automatic Grade : Automatic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese