Flash Dryer

Price 2000000 INR/ Piece

Flash Dryer Specification

- Product Type

- Flash Dryer

- Material

- Stainless Steel

- Capacity

- Up to 1000 kg/hr Kg/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Power

- 18 - 75 kW (depending on model) Watt (w)

- Voltage

- 380-415 V Volt (v)

- Weight

- Approx. 2200 kg Kilograms (kg)

- Color

- Silver Grey

- Heating Source

- Electric, Steam, or Gas

- Surface Finish

- Mirror/Matte as per industry standard

- Noise Level

- Less than 85 dB

- Evaporation Efficiency

- High thermal efficiency with rapid heat transfer

- Design Type

- Vertical Continuous-flow

- Application

- Suitable for drying powders, granules, and pastes in food and chemical industries

- Safety Features

- Overload protection, emergency shutdown system

- Drying Temperature Range

- 80C to 300C (adjustable)

- Air Flow Configuration

- Co-current or Counter-current

- Minimum Order Quantity

- 1 Unit

- Feed Method

- Screw feeder or pneumatic conveying

- Exhaust System

- Cyclone separator with bag filter

- Mounting

- Skid-mounted or foundation-mounted as per demand

- Moisture Evaporation Capacity

- 10-750 kg/hr

Flash Dryer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

About Flash Dryer

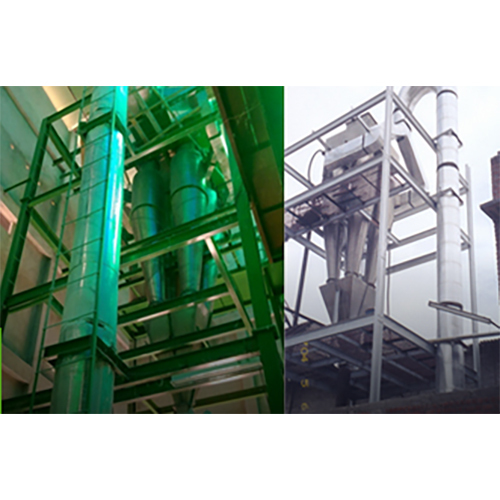

Flash Dryer

We offer Flash dryers in three type negative draft (negative pressure drying), positive draft (positive pressure conveying) and balance draft (positive-negative conveying).

Flash type or pneumatic dryer are used for removing surface or unbounded moisture from a feed. Technology behind it is relatively low residence time and moisture is flashed off, a consequential amount of evaporative cooling takes place allowing higher inlet temperature to be used without excessively heating the product.

We offer a complete flash dryer package including hot air generation system via steam or gas, feeding system, cyclones or air bags, wet or dry scrubber for capturing fines, product collection section, control & instrumentation. We also provide optional accessories like feed preconditioning depending upon application, product conveying cooling.

Main features:

- Strong construction

- Available in AISI 304 & AISI 316

- Low residence time

- Various feeding arrangement available

- Range of feed disintegrator

- Fully or partly automation

- Hot air generation system via steam or gas

Applications

- Starch

- Gluten

- Starches from Potato, Corn, Wheat, Cassava, etc.

- Wheat and Corn Gluten

- High protein fodder DDGS

- Minerals

- Cellulose

- Pigments and dyestuffs

- Fine chemicals

- Zirconium Hydroxide

- Sodium Ferro-Cyanide and Sulphate

- Metal powders

- Precipitated Calcium Carbonate

- Silicate

- Bethonite

- Alfa Ash

- Carbon

- Gravy powder

Falling Film Evaporator

A falling film evaporator is used in industries to concentrate liquid especially heat sensitive materials In this type of evaporators the liquid is feed from the top of the evaporator design of the product distribution system in the evaporator is such that the product wetting of the tubes should be full and evenly.

The product is distributed into the heating tubes in a form of thin layer and it flows downwards at boiling temperature and start evaporating.

The product and the vapors goes into the separator where the both is separated and vapors is forwarded to next effect. This type of evaporators can be operated with very low temperature differences between the heating media and the liquid. The effect of this type evaporator depends of the capacity and type of product. While designing number of effect is calculated considering steam economy and cost.

Applications

- Glucose/Dextrose/Maltose/Fructose

- Milk

- Honey

- Fruit Juices

- Tomato Juice

- Malt Extract

- Sugar Cane Juice

- Invert Sugar

- Coffee Extract

- Tea Extract

- Herbal Extract

- Soy milk

- Tea extract

- Distillery Waste

- Tea Extract

- Water Effluent etc.

Chemical & Pharmaceuticals

- Salt

- Enzymes

- Gelatine/Glue

- Sodium Sulphate

- Dye

- Effluent

- Caustic Soda

- Phosphoric Acid etc.

Highly Efficient Drying Technology

Enjoy rapid and uniform drying for powders, granules, and pastes with our continuous-flow Flash Dryer. Leveraging advanced heat transfer mechanisms, this dryer ensures high moisture evaporation rates of up to 750 kg/hr, making it highly suitable for demanding industrial applications. Adjustable temperature controls and air flow configuration options enhance operational versatility for various material requirements.

Versatile Design & User-Friendly Operation

Designed with flexibility in mind, this Flash Dryer supports both electric, steam, or gas heating, and is available in skid-mounted or foundation-mounted formats. The PLC-based automatic control system simplifies parameter adjustment and ensures safe operation, while noise levels remain below 85 dB, supporting a comfortable working environment.

FAQs of Flash Dryer:

Q: How does the adjustable temperature range benefit the drying process in the Flash Dryer?

A: The adjustable temperature range of 80C to 300C allows precise control over drying conditions, ensuring optimal moisture removal for different materials. This flexibility enables the dryer to handle a variety of powders, granules, and pastes without compromising product quality.Q: What materials and industries can use this Flash Dryer effectively?

A: This Flash Dryer is ideal for applications in the food and chemical industries, and is suitable for drying a wide range of bulk solids including powders, granules, and pastes. Its stainless steel construction meets industry hygiene and durability requirements.Q: When is it recommended to use co-current versus counter-current air flow configuration?

A: Co-current air flow is typically used for heat-sensitive materials, as the product and hot air move in the same direction, preventing overheating. Counter-current flow is more effective for materials requiring a higher degree of drying, as it allows better heat exchange.Q: Where can the Flash Dryer be installed, and what are the mounting options available?

A: Installation can be customized as per the facilitys requirements. The dryer is available in both skid-mounted and foundation-mounted versions, making it suitable for both new and existing production lines.Q: What is the process for feeding materials into the Flash Dryer?

A: Materials can be introduced either through a screw feeder for precise metering or via pneumatic conveying for bulk feeding. This allows efficient handling and consistent drying results.Q: How does the exhaust system ensure clean and safe operation?

A: The dryer is equipped with a cyclone separator and bag filter which efficiently capture dust and prevent particulate emissions, maintaining a safe and clean operating environment in compliance with regulatory standards.Q: What are the key benefits of choosing this Flash Dryer for industrial drying needs?

A: Key benefits include high thermal efficiency, rapid drying rates, automatic PLC-based controls, low noise operation, versatile mounting and heating options, and enhanced safety features like overload protection and emergency shutdown systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flash Dryer Category

Drum Dryer

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : PLC Control

Warranty : 1 Year

Color : Silver

Tube Bundle Dryer

Price 4500000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : Human Machine Interface

Warranty : 1 Year

Color : Red

Rotary Dryer

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : Human Machine Interface

Warranty : 1 Year

Color : Silver Brown

Spin Flash Dryer

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : PLC Control

Warranty : 1 Year

Color : Silver Brown

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese